ValvePro Limited are the sole UK representative of Carter Process Control products and services.

Carter Process Control GmbH are based in Austria, employ highly skilled control valve engineers, and have more than 30 years industry experience providing high quality engineered control valve trim solutions for severe service applications. Our trims are uniquely supplied to both end users and OEM valve manufacturers.

Carter Process Control specialises in providing severe service multipath control valve trims which are:

- Direct replacements for the OEM parts.

- Specially engineered to solve problems and supplied as an upgrade to the existing installed valve.

- Engineered to fit into any OEM valve manufacturers valve for supply on a new project.

Additionally CPC stocks all soft goods for CCI and BTG valves including Packings, Gaskets and Balance Seals. Included in our inventory is also a large selection of Actuator repair kits.

Recent addition to our stocking program has included the complete range of spray water nozzles that can be ordered and shipped the same day.

Carter Process Control is an ISO 9001:2008 certified company and is committed to quality excellence. All parts are manufactured in full accordance with our ISO Quality Program. Our quality program has successfully undergone audits by numerous customers and industry organisations. Carter Process Control is globally represented and providing parts and service in all major industrialised countries.

CPC’s unique ability to design, engineer and manufacture replacement spare parts for Severe Service Multipath Control Valves has positioned us as a major supplier to many world renowned companies.

Disclaimer: “ValvePro Limited and Carter Process Control GmbH are not affiliated with IMI or CCI or their affiliated companies”

Severe Service Replacement Parts

CPC means performance, value, and customer service.

Direct replacements for CCI Disk Stack technology in Severe Service Control Valves.

- 100% interchangeability.

- No new inventory needed.

- No retraining of personnel.

- Parts identified with OEM part number and CPC unique part number for easy traceability.

- CPC standard deliveries are the fastest in the industry.

Our new advanced techniques of manufacturing have cut the time for producing each disk plate by at least half

- Disk Stacks

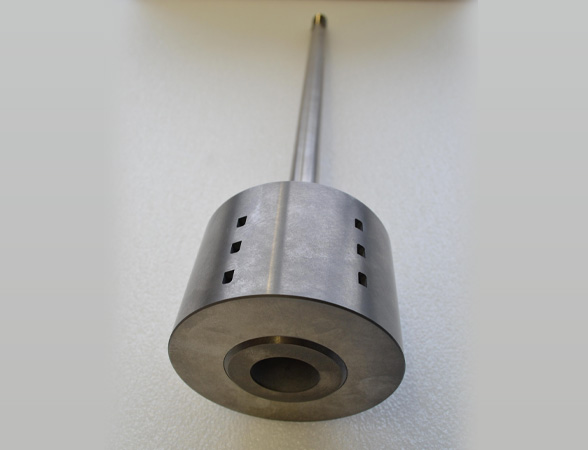

- Plug/Stem Assemblies

- Seat Rings

- Cages

- Metal Seals

- Guide Bushes, etc.

In addition to the control valve trims CPC stocks all valve and actuator soft goods ready for immediate shipping.

Upgrade Solutions

- An engineered solution incorporating CPC designed trim into an existing valve body

- Fits into most globe & angle cage guided valves

- CPC assumes complete responsibility of the valve

- Full documentation provided

- Provide different technology into existing valve bodies – improve life/operating of the valve

- Reuses existing high priced components, body, actuator, etc.

- Saves cost of piping modifications

- Lower installation costs plant downtime is shorter

Example: CPC were asked to help solve a continuous problem with a well known manufacturers control valve that was effectively failing in service every 6 months or less. CPC was able to come up with a complete new trim solution that was presented to the customer and subsequently ordered. The trim has been in trouble free operation since installation and has no sign of wear or failure.

Comments from the customer – “With regards the valve operation, both units have been returned to service and are tight with respect to the pressure boundary. From the limited indication we have it would appear also that the valves have good shut-off, we have similarly experienced no control issues.”

Fully Sintered Tungsten Carbide Multipath Trims

Carter Process Control GmbH has designed and engineered(Patent Pending) a Solid Tungsten Carbide multi Stage Severe Service Trim for Control Choke Valves with “NO” brazing, EDM or Erosion. The product is called the “JACK” trim standing for Joint Adverse Carbide Knowledge.

As a non valve manufacturer but with extensive control valve trim manufacturing experience CPC is uniquely positioned to supply its trim to any valve manufacturer or end user that requires a severe service multistage pressure reduction trim. Available in an almost limitless range of sizes and pressure reduction stages to fit the most arduous of operating conditions.

Replacement Spray Water Nozzles

Carter Process Control GmbH has spent a considerable amount of time designing and testing a complete range of interchangeable spray water nozzles for existing installations. These desuperheating nozzles are direct replacements to the OEM and are designed to be 100% equivalent or better but with large savings against the OEM price.

Each size of nozzle is now stocked in considerable quantities ready for immediate despatch upon customer’s request.