Replacement Steam Trap Assembly

Application:

Turbine Hall

Media:

Superheated Steam

Challenge:

This Power Station has very stringent rules regarding the procurement and manufacture of all pressure containing equipment. These rules detail the Quality Systems and Certification that are required with the Purchase of every Valve, Pipe, Pump or other Pressure Containing Equipment.

The OEM has moved production of the Piping King Assembly to India with the Material, Welding, Testing and all Certification originating from their Indian manufacturing facility. This does not comply with the Clients Procurement Document. As such, ValvePro were tasked with finding an alternative solution which complies with material requirements, is commercially competitive and improves on the OEM quoted lead time of 28 working weeks.

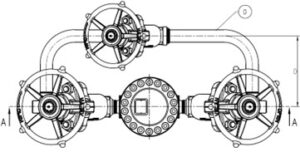

Figure 1a: Plan view.

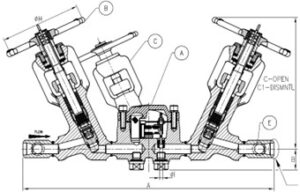

Figure 1b: Assembly

ValvePro Solution:

Firstly, we must understand the purpose and function of the Velan assembly to offer a competent technical solution for the client. The piping assembly consists of 2 x 1” Globe Valves, 1 x 1” Steam Trap and a ¾” Bypass Line complete with Globe Stop Valve. The function of the system is to be able to isolate the line to perform routine maintenance on the steam trap, drain condensate etc whilst keeping the line pressure via the bypass arrangement. See Figure 1a & 1b which visually shows component assembly layout.

ValvePro Ltd is the European Master Distributor for Conval Inc. who manufacture High Pressure, Small Bore Globe, Gate & Metal Seated Ball valves for Severe Service applications which made them a perfect fit for this application. In addition to this, Conval procure their material from North America and Italy meaning they are compliant with Client Procurement requirements. We were also able to utilise our established supply chain partners to procure the correct Steam Trap with an acceptable Material Origin with full 3.1 certification, ensuring full traceability of parts for site Quality Engineers.

ValvePro scope of supply included:

- 1” Conval Globe Stop Valve (Inlet Isolation)

- 1” Conval Globe Stop-Check Valve (Outlet Isolation & Non-Return)

- ¾” Conval Globe Stop Valve (Bypass Isolation)

- 1” High Pressure Steam Trap

- 2 x ¾” Bypass Pipes @ 90°

- 2 x Tee Reducers (1 ¼” x 1” x ¾”)

- Welding to create Assembly + NDE

- Quality Dossier, including 3.1 certification for all material.

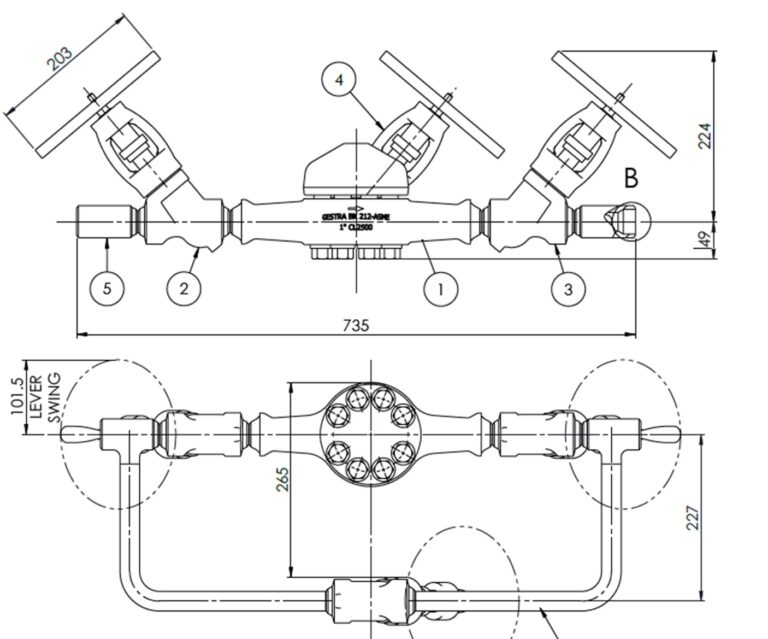

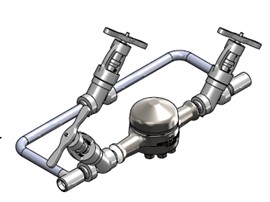

The ValvePro solution provides similar Fit, Form and Function as the existing Velan unit. When the system is under normal operation, the bypass line is isolated via the Conval Globe Stop Valve, the Steam Media enters through the Inlet Globe Valve and into the steam trap where any condensate is released and exits through the Outlet Conval Globe Stop-Check Valve. The outlet valve has been specified Non-Return as a means to protect the Steam trap in occurrence of back pressure where the Disc will Seat using the line pressure. When Operational Maintenance is required the Bypass Valve is opened to allow pressure to vent around the system, and the Inlet and Outlet Isolation Valves are closed to protect the operator from line pressure in the system. Please refer to Figure 2 below which illustrates the ValvePro Solution as an assembly.

Figure 2: ValvePro Steam Trap Assembly

Conclusion:

ValvePro Ltd were able to Design, Procure, Fabricate and Certify a solution within 8 working weeks that is both technically compliant and supplied at a price point that is competitive for the client. Furthermore, all parts were manufactured using acceptable Origin Materials with 3.1 Certification to support, thus meeting the criteria of the PS stringent requirements.