ValvePro Limited can supply Conval Globe, Check & Strainer valves for Drain and Vent applications.

Market sectors and plant processes include Power (Nuclear, Combined Cycle Gas, and Conventional), Refining, Petrochemical, and Oil & Gas among others.

- In-line maintainable

- Reduced downtime

- Reduced welding & NDE costs during outage

- Zero leakage

- Stock availability for quick turnround

Manufacturing range

- 0.5″ to 4″ (DN15 to DN100)

- ANSI 900 to ANSI 4500 Ratings (Standard, Intermediate, and Limited Classes also included)

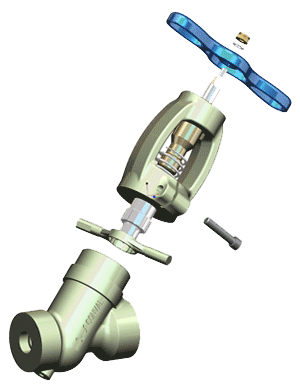

- T-pattern, Y-pattern, and Angle pattern body styles available

Materials of construction

ASME Forged and Cast Carbon, Alloy and Stainless Steels materials including:

- AS105, SA182, F22, F91, F316 Stainless Steel

- SA216 WCB, SA217 WC9, C12A, SA351 CF8M Stainless Steel

Other materials on request

Design features

- In-line maintainable

- Zero body leakage

- Zero seat leakage

- Zero Stem leakage

- Internal Gland Wrench (IGW)

- Robust Stem-Disc engagement

- Backseat arrangement

Certification

Across the whole Conval range, valves are designed and certified to all major industry standards including ASME, API, NACE, and ATEX. In addition, Conval are accredited with the ‘N’ stamp to install valves in nuclear sensitive areas as well as PED for the European market.

Key benefits

- In-line maintainable

- Reduced downtime

- Reduced welding & NDE costs during outage

- Zero leakage

- Stock availability for quick turnround